- Ginazhao@wanglumaterial.com

- Mon - Sat at 7:00AM to 9:00PM

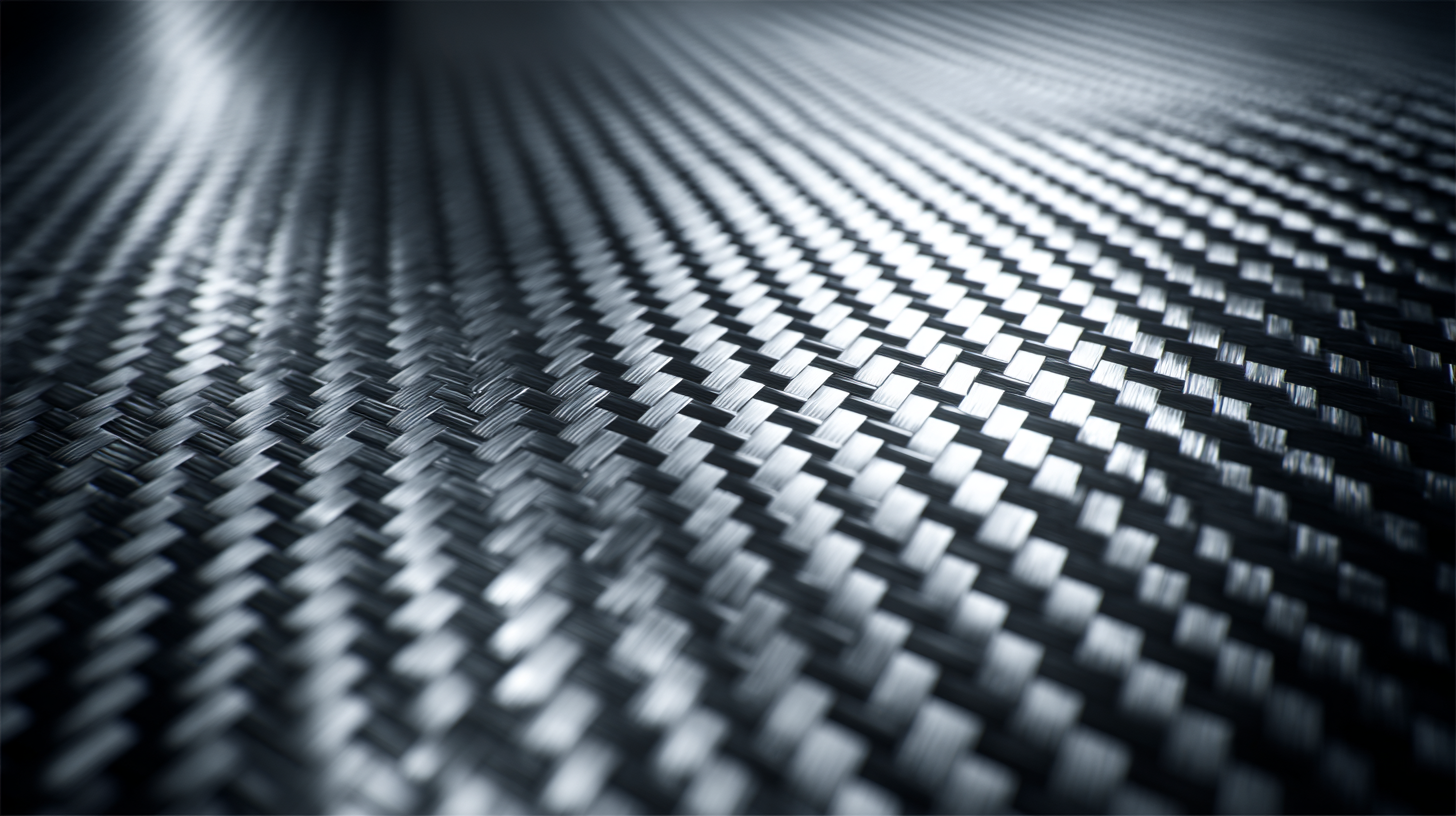

The emergence of Carbon Fiber Panels is significantly transforming the landscape of modern design and engineering, offering unprecedented advantages in strength and lightweight properties. According to a report by Markets and Markets, the carbon fiber market is projected to reach $5.2 billion by 2025, driven by its extensive applications across various industries including aerospace, automotive, and sports equipment. Carbon fiber composites boast a tensile strength five times greater than that of steel while being only a fraction of the weight, making them a crucial material in high-performance engineering.

As innovators increasingly leverage the unique properties of Carbon Fiber Panels, they are not only enhancing design aesthetics but also optimizing performance and sustainability. This shift represents a pivotal moment in material science, laying the groundwork for future advancements in engineering and architecture.

Carbon fiber has emerged as a transformative material in modern design and engineering due to its unique properties, including high strength-to-weight ratio, corrosion resistance, and flexibility. These attributes make carbon fiber an excellent alternative to traditional building materials, particularly in construction where reduced weight and increased durability are paramount. With the advancements in manufacturing technologies, such as additive manufacturing and filament extrusion, the potential applications of carbon fiber composites have expanded significantly, enabling more innovative designs that were previously unattainable.

Research into the synergy between carbon nanotubes and carbon fiber composites has shown promising results, enhancing mechanical properties and interfacial structures. This optimization allows for lightweight materials that do not compromise on strength, essential for both structural integrity and energy efficiency. Furthermore, new applications for carbon fiber composites, such as in automotive components and specialized functions like electromagnetic wave absorption, highlight the versatility of this material. As the manufacturing processes continue to evolve, the integration of carbon fiber into various design applications promises to revolutionize not only engineering but also industries like aerospace and automotive, paving the way for more sustainable and efficient practices.

Carbon fiber panels are making significant strides in modern engineering, heralding a new era of design efficiency and lightweight construction. According to a recent report by MarketsandMarkets, the global carbon fiber market is projected to reach USD 5.72 billion by 2026, growing at a CAGR of 10.9% from 2021. This remarkable growth is fueled by the material's exceptional strength-to-weight ratio, making it ideal for aerospace, automotive, and construction applications. For instance, in the aerospace sector, manufacturers are increasingly utilizing carbon fiber panels to reduce the weight of aircraft, thereby improving fuel efficiency and reducing emissions.

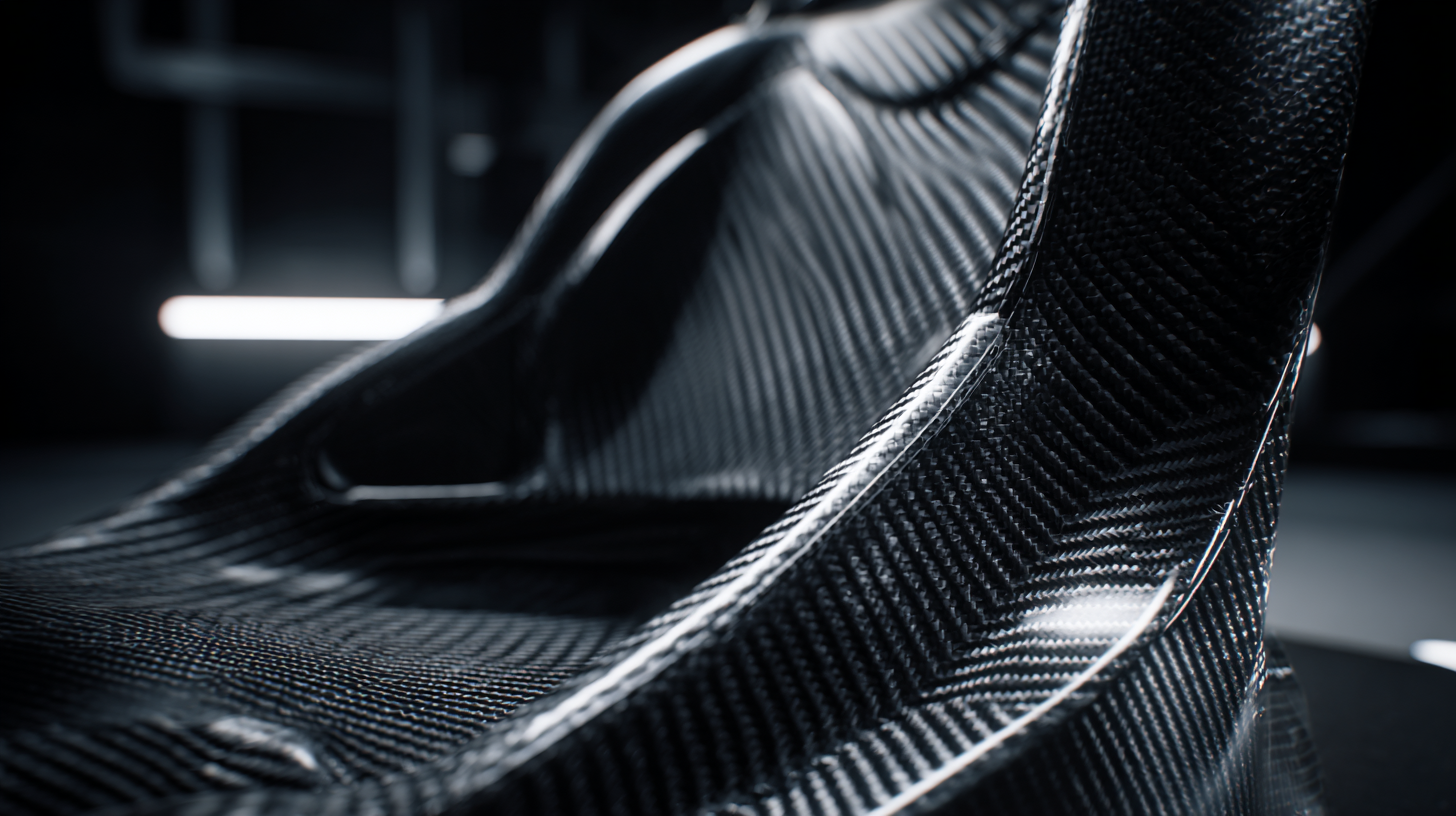

In the automotive industry, the trend toward lightweight materials is revolutionizing vehicle design. A study by McKinsey & Company highlighted that using carbon fiber can reduce vehicle weight by 30-50%, significantly enhancing performance and efficiency. High-profile manufacturers are adopting carbon composites in their models to meet stringent environmental standards while boosting the overall safety and durability of the vehicles. Additionally, in the construction sector, carbon fiber-reinforced polymers are being employed to strengthen existing structures and enable innovative architectural designs, allowing for greater flexibility and creativity in urban development. This array of applications underscores the transformative potential of carbon fiber panels in modern engineering projects.

Carbon fiber panels are becoming a game-changer in architectural designs, thanks to their remarkable strength-to-weight ratio and unparalleled durability. According to a report by MarketsandMarkets, the global carbon fiber composites market is expected to grow from $22.8 billion in 2020 to $41.5 billion by 2025, reflecting the increasing adoption of these materials in various industries, including construction. Their lightweight nature allows architects to create innovative and bold designs that would be unfeasible with traditional materials. Moreover, their high tensile strength ensures stability, making them suitable for both structural applications and aesthetic elements.

Incorporating carbon fiber panels into architectural designs can enhance both functionality and visual appeal. For instance, these panels can be used for façade cladding, providing not only an eye-catching surface but also contributing to energy efficiency by reducing building weight and improving insulation. Additionally, their resistance to environmental factors like UV radiation and moisture ensures a long lifespan, leading to lower maintenance costs. High-profile projects, such as the use of carbon fiber in the Tesla Gigafactory, showcase how these materials can spur sustainable advancements while pushing the boundaries of conventional architecture. By embracing carbon fiber, professionals can leverage its unique properties to create cutting-edge structures that stand the test of time.

| Property | Carbon Fiber Panels | Traditional Materials (e.g., Aluminum, Steel) |

|---|---|---|

| Weight | Lightweight (30% - 50% lighter) | Heavier |

| Strength | High tensile strength | Moderate tensile strength |

| Corrosion Resistance | Excellent | Requires coatings |

| Flexibility in Design | Highly customizable shapes | Limited shapes |

| Cost | Higher initial cost | Lower initial cost |

| Sustainability | Recyclable options available | Limited recycling options |

Carbon fiber panels are gaining traction in modern design and engineering due to their remarkable strength-to-weight ratio and versatility. However, it’s essential to conduct a thorough cost-benefit analysis when considering their use in manufacturing. For example, while the initial setup cost for a carbon fiber manufacturing plant can be substantial, research indicates that the long-term benefits, such as reduced material waste and enhanced product performance, often outweigh these expenditures. The incorporation of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composites can lead to significant savings in production costs over time, especially when evaluated through a life cycle analysis.

Tips: When planning a project involving carbon fiber, consider conducting a comprehensive life cycle assessment (LCA) to identify potential cost-saving strategies early in the design phase. Exploring recycled carbon fiber options can also offer an eco-friendly way to reduce costs while maintaining performance standards. Additionally, investing in efficient manufacturing methods, such as advanced fabrication and testing techniques for fiber-reinforced polymers, can improve overall production efficiency and sustainability.

This chart examines the cost-benefit ratio of using carbon fiber in manufacturing. The vertical axis represents a scale from 1 to 10, illustrating various factors such as material cost, production time, weight reduction, durability, and design flexibility, highlighting the advantages and challenges of integrating carbon fiber into modern design and engineering.

The future of carbon fiber technology is poised for remarkable advancements, with industry reports predicting a significant market growth. According to a report by Markets and Markets, the carbon fiber market is expected to reach $5.4 billion by 2025, driven by increased demand in automotive, aerospace, and sports sectors. This growth hints at the potential for more innovative materials that enhance design flexibility and functionality. As carbon fiber becomes more affordable due to advances in production technologies, its integration into mainstream products is likely to increase, transforming traditional design approaches.

As we look ahead, one of the most promising trends is the development of bio-based carbon fiber composites. These materials not only promise sustainability but also offer comparable performance to conventional carbon fiber. The adoption of these innovative products can lead to significant reductions in carbon footprints, making them appealing to eco-conscious consumers and businesses alike.

Tips: When considering carbon fiber for your next project, keep in mind the importance of supplier certification and material transparency. Conduct thorough research on the latest advancements to stay ahead of your competitors. Additionally, integrating carbon fiber can enhance not only the performance but also the aesthetic appeal of your designs, enabling you to create standout products in a crowded market.